ABOUT US

Ha Viet Petroleum service., JSC was founded in 2013 in Vung Tau City, Viet Nam. We are is a leading anticorrosion, insulation, scaffolding, PFP coating… related services on FPSO, FSO, Platform… for the Viet Nam’s Oil and Gas industry and certain other industrial applications.

With a range of fully tailored services in the oil and gas sector, both on shore and offshore. Our main services include all types of surface preparation such as blast cleaning using abrasive grits, UHP waterblasting, slurry blasting and all types of mechanical tool preparation to surfaces, Scaffolding, Insulation service…

Our personnel are experienced and trained to high standards with qualified NACE, BGAS and Institute of Corrosion Paint and Fireproofing Inspectors on hand to maintain and enhance the services on offer to our customers.

OUR VISSION AND MISSION

VISSION

Our vision is to be a leading and outstanding engineering services firm in Vietnam, through our work, excellence, consciousness of client’s needs and effective application of organizations skills for the achievement of greater market share, profitability and clients’ satisfaction.

MISSION

In order to achieve our vision, Haviet’s mission is to provide innovative, practical and top-quality products and services to our customers, as well as rewarding, imparting knowledge and providing a conducive working environment to our employee.

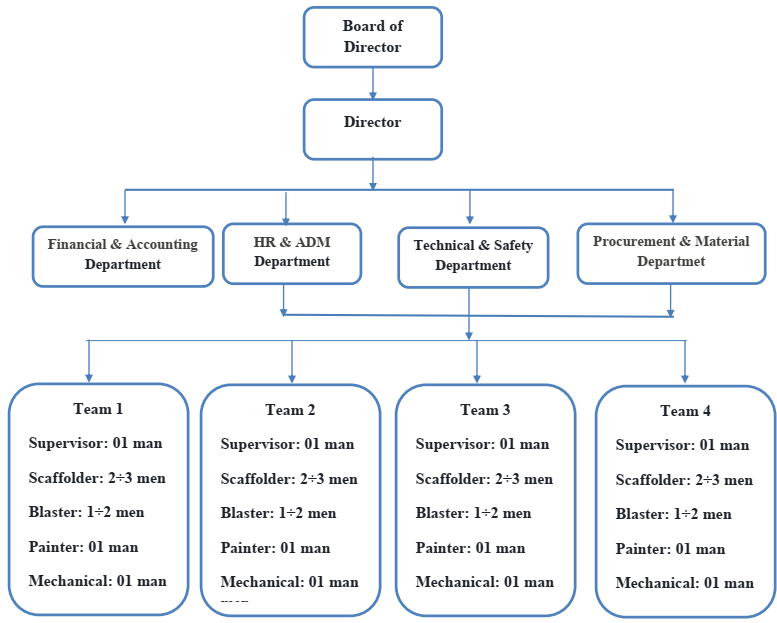

COMPANY ORGANIZATIONAL CHART

LICENSE

Company name: Ha Viet Petroleum Service Joint Stock Company

The legal representative: Mr. Le Hoang Hoi

Position: Director

Headquarter:

Adress: 132/39 Nguyen Tri Phuong, Ward 7, Vung tau City, Ba Ria-Vung Tau province.

Telephone: 0254 3855 491 – Fax:0254 3855 491

Email: info@daukhihaviet.vn

Workshop:

Address: Downstream Port 65A 30-4 Road, Thang Nhat Ward, Vung Tau City

Telephone: 064 3855 491 – Fax: 064 3855 491

Email: info@daukhihaviet.vn

ISO 9001 & OSHAS 18001

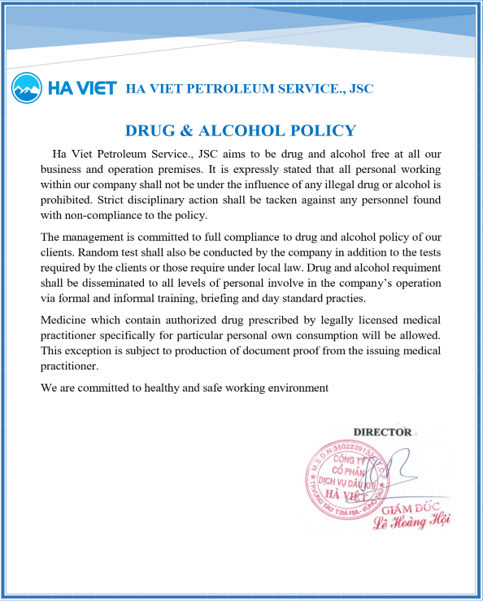

COMPANY POLICY

Our management put high commitment towards HSE (Health, Safety and Environment) awareness among the staffs and Client. The Company Policy has establish to ensure in all the work, safety is our first priority not only for company but also for themselves.

KEY PARTS OF THE HA VIET QMS INCLUDE:

- On-going Employee Training

- Standardized Workflows

- Quality Checklists and Forms

- Quality Audits

- Continuous Learning and Improvement

QHSE SYSTEM

We utilize a QHSE Management System to continually monitor, audit and improve our services and internal practices. These Systems have been developed in line with the OHSAS 18001:2007 and ISO 9000:2015 series of management system standards and best practices. They ensure legal compliance and an overarching commitment to safety, health, quality and environmental matters and risk management.

Element 1: Management Commitment

The Haviet management team establishes the purpose and direction of the organization, and maintains an inclusive internal culture. Top management commitment is an essential part in ensuring the QHSE MS is established, implemented, maintained, and continually improved.

Element 2: Resource Management

Resource Management is the way in which the Haviet management team allocates financial, personnel, and equipment resources to its operations.

Element 3: Service Realization and Delivery

Service Realization and Delivery ensures our solutions and services meet all project requirements. This element includes:

- Planning of Service Realization

- Determination and Review of Project Requirements

- Development

- Purchasing

- Execution of Service

Element 4: QHSE Administration

QHSE Administration processes include:

- Process Interaction

- Identification and Evaluation of Environmental Aspects

- Hazard Identification, Risk Control and Contingency Planning

- Management of Change

- Emergency Response Planning

- Incident and Accident Investigation

Element 5: Measurement, Analysis, Monitoring, and Improvement

Haviet implements monitoring, measurement, analysis, and improvement processes needed to:

- Ensure conformity to SRP requirements

- Monitor and measure the extent to which the organization’s quality, health, safety, and environmental objectives are met and fulfillment of compliance obligations

- Continually improve and monitor the effectiveness of the QHSE MS and controls